Quality Control

At SAGAR ENTERPRISES, quality is not just a checkpoint — it’s a culture, a mindset, and a non-negotiable promise. In industries such as aerospace, defense, medical, and automotive, we understand that even the smallest deviation can have significant consequences. That’s why every component we manufacture undergoes rigorous quality control protocols to ensure complete compliance with customer requirements and global standards.

Our quality assurance process begins long before production starts. From raw material verification and detailed process planning to in-process inspections and final audits, every stage is meticulously monitored and documented. We utilize advanced inspection equipment, including CMMs, surface finish testers, and high-precision gauges, to validate critical dimensions and maintain strict tolerances.

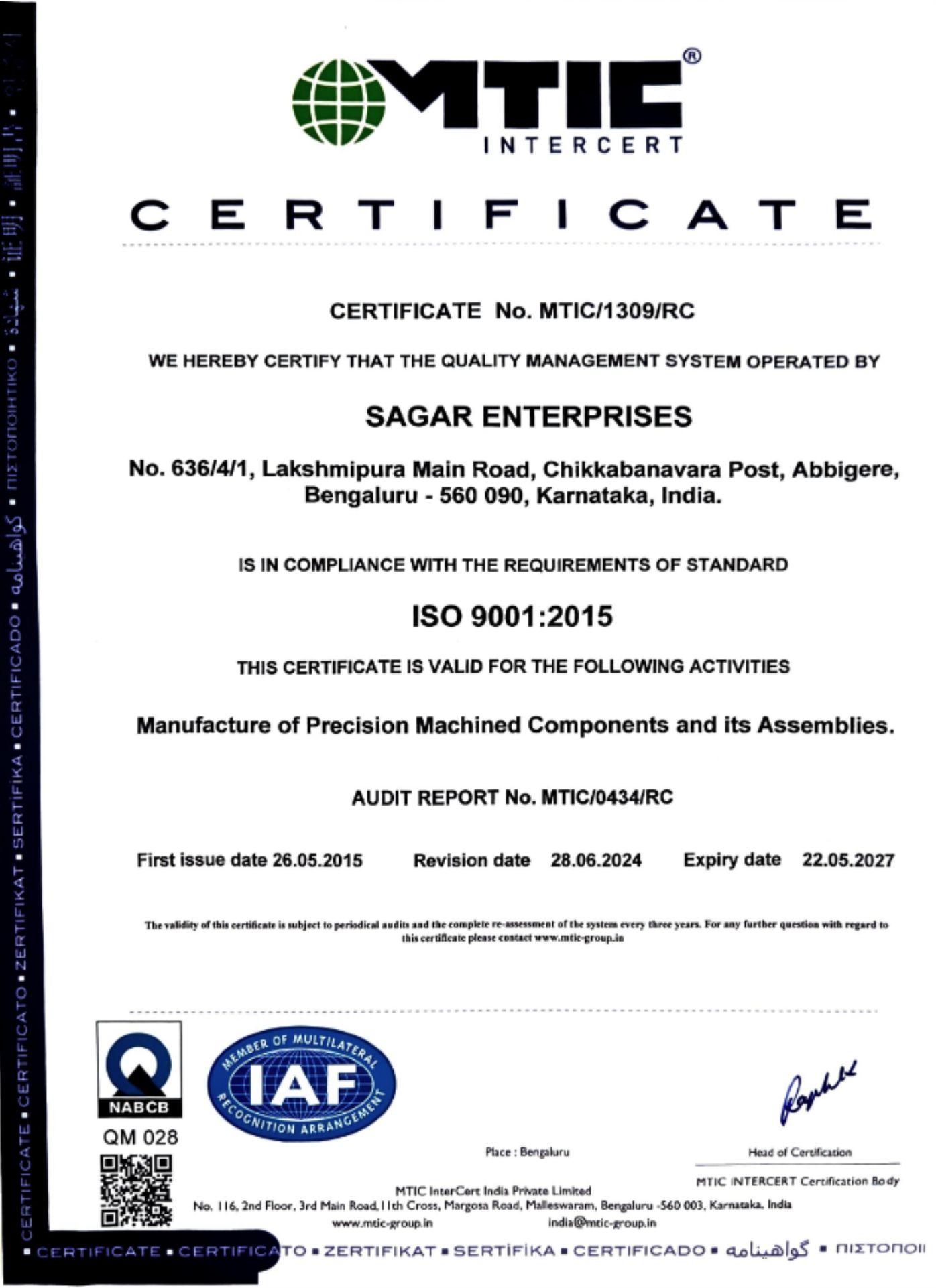

Backed by ISO-certified systems, our experienced quality team works collaboratively with production and engineering teams to ensure flawless execution at every stage. This integrated, end-to-end approach allows us to consistently deliver zero-defect components, enhancing the reliability, safety, and performance of every product we manufacture.

At SAGAR ENTERPRISES, quality is engineered into every part — because our clients deserve nothing less than perfection.

Inspection Equipment

Our Quality Control Lab is Equipped With

To ensure precision and consistency in every component, our in-house Quality Control Lab is equipped with a wide range of calibrated inspection instruments, including:

-

Vernier Calipers & Micrometers – For accurate linear and dimensional measurements.

-

Height Gauges – For precise vertical and step height measurements.

-

Bore & Thread Gauges – To inspect internal diameters and threaded features with accuracy.

-

Dial Indicators – For alignment checks and runout verification.

-

Surface Roughness Testers – To assess surface finish and verify compliance with tolerance standards.

-

Coordinate Measuring Machine (CMM) – Available on request for advanced dimensional inspection of complex geometries.

At SAGAR ENTERPRISES, every inspection instrument is regularly calibrated to maintain measurement accuracy and reliability — ensuring that every component we deliver meets global quality benchmarks.

Our Commitment

At SAGAR ENTERPRISES, we believe quality isn’t a checkbox — it’s a culture deeply embedded into every stage of our operations. Quality is a dynamic, ongoing commitment, not a static outcome. Every team member — from machinists to managers — is trained to identify potential issues, implement corrective actions, and uphold best practices that prevent defects before they occur. For us, continuous improvement isn’t just a policy — it’s our way of working.

Our robust Quality Management System (QMS) supports both high-mix and high-volume production. Whether it’s a one-off prototype or a recurring production batch, our inspection protocols are tailored to the complexity, material, and functional requirements of each part. Our fully equipped Quality Control Lab — featuring micrometers, bore gauges, surface finish testers, and CMM (available on request) — ensures every dimension, surface finish, and fit is verified with precision. All inspection data is fully traceable, with complete documentation available to support compliance, certifications, and audits.

Customers across the aerospace, defense, medical, and automotive sectors trust us to deliver components that perform flawlessly — even in the most demanding environments. Our mission is simple: to deliver zero-defect parts with maximum reliability, every time.

When you partner with SAGAR ENTERPRISES, you gain more than just a supplier — you gain a quality-driven team committed to protecting your performance, reputation, and trust with every component we produce.

Our Quality Standards

Our Quality Assurance Pillars

At SAGAR ENTERPRISES, our quality assurance framework is built on four key pillars that ensure every component meets the highest standards of precision, consistency, and compliance.

1. Dimensional Accuracy

We utilize calibrated measuring tools, gauges, and advanced inspection systems to validate every dimension against design specifications — ensuring exact tolerances are achieved, part after part.

2. Process Control

Quality is embedded into every stage of production. From raw material verification to in-process checks and final inspections, each step is governed by strict quality checkpoints and standardized protocols.

3. Documentation & Traceability

Every component is uniquely tagged and documented, providing complete traceability throughout its lifecycle. This supports accurate audits, non-conformance analysis, and ensures full regulatory compliance.

4. Certifications & Standards Compliance

Our quality management systems are aligned with ISO and industry-specific standards, ensuring globally compatible, reliable, and audit-ready processes and products.