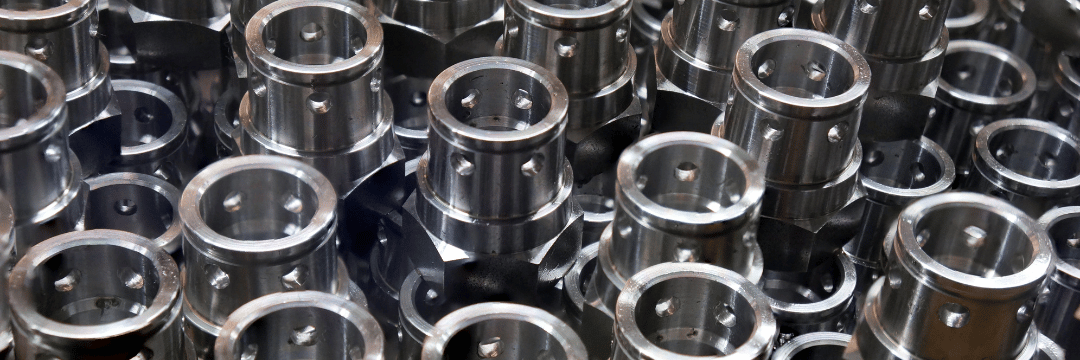

Precision Components

At SAGAR ENTERPRISES, precision isn’t just a standard — it’s a promise.

We specialize in the design and manufacturing of high-accuracy precision components that serve critical applications across industries such as aerospace, automotive, medical, defense, and industrial machinery.

Every component we produce is a reflection of engineering excellence, material mastery, and manufacturing precision — ensuring performance, durability, and consistency you can trust.

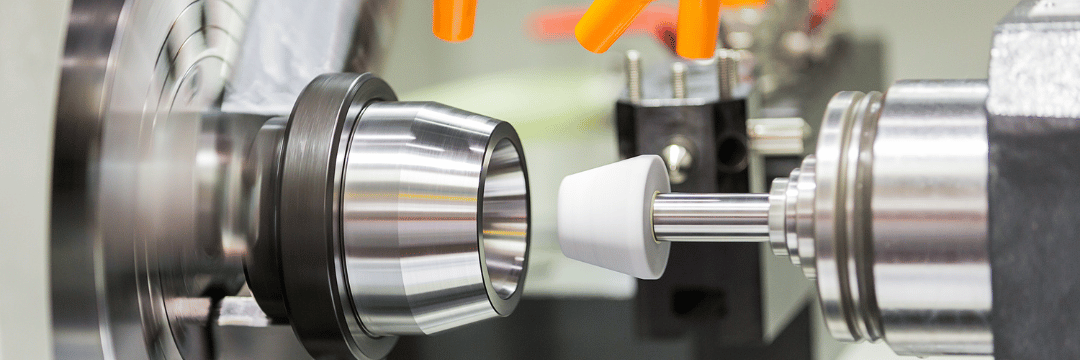

Our Expertise

Our precision components are manufactured using advanced CNC and VMC machining technologies, ensuring tight tolerances, excellent surface finish, and dimensional accuracy. We work with a wide range of materials, including:

-

Stainless Steel

-

Aluminum

-

Titanium

-

Brass

-

Copper

-

Engineering Polymers

From prototypes to large-scale production, our team delivers components that meet international standards and exceed customer expectations for performance and reliability.

Types of Precision Components We Manufacture

-

Aerospace Components – High-strength, lightweight parts for flight-critical applications.

-

Automotive Components – Engine, transmission, and suspension parts designed for long-term durability.

-

Medical Components – Biocompatible and sterile-safe precision parts for medical devices and instruments.

-

Defense Components – Rugged, high-tolerance parts designed for reliability under extreme conditions.

-

Industrial Components – Precision-engineered parts for automation, machinery, and heavy equipment.

Features

-

⚙️ Tight Tolerance Machining – Micron-level precision for complex and intricate designs.

-

🧠 Custom Engineering Support – Tailor-made components based on client drawings and specifications.

-

🏭 End-to-End Manufacturing – From design to finishing, all processes are handled in-house for full quality control.

-

🔍 Advanced Inspection & Testing – Each component is verified using coordinate measuring machines (CMM) and digital inspection systems.

-

💡 Material Expertise – Specialized in handling exotic metals and alloys for critical applications.

Benefits

-

✅ Uncompromised Accuracy: Perfect fit and function in every application.

-

⏱️ Reduced Lead Times: Streamlined production ensures timely delivery.

-

💰 Cost Efficiency: Smart machining and material optimization minimize waste.

-

🛡️ Long-Term Reliability: Built for endurance in high-stress environments.

-

🌍 Global Quality Standards: Manufactured to meet ISO, CE, and industry-specific certifications.