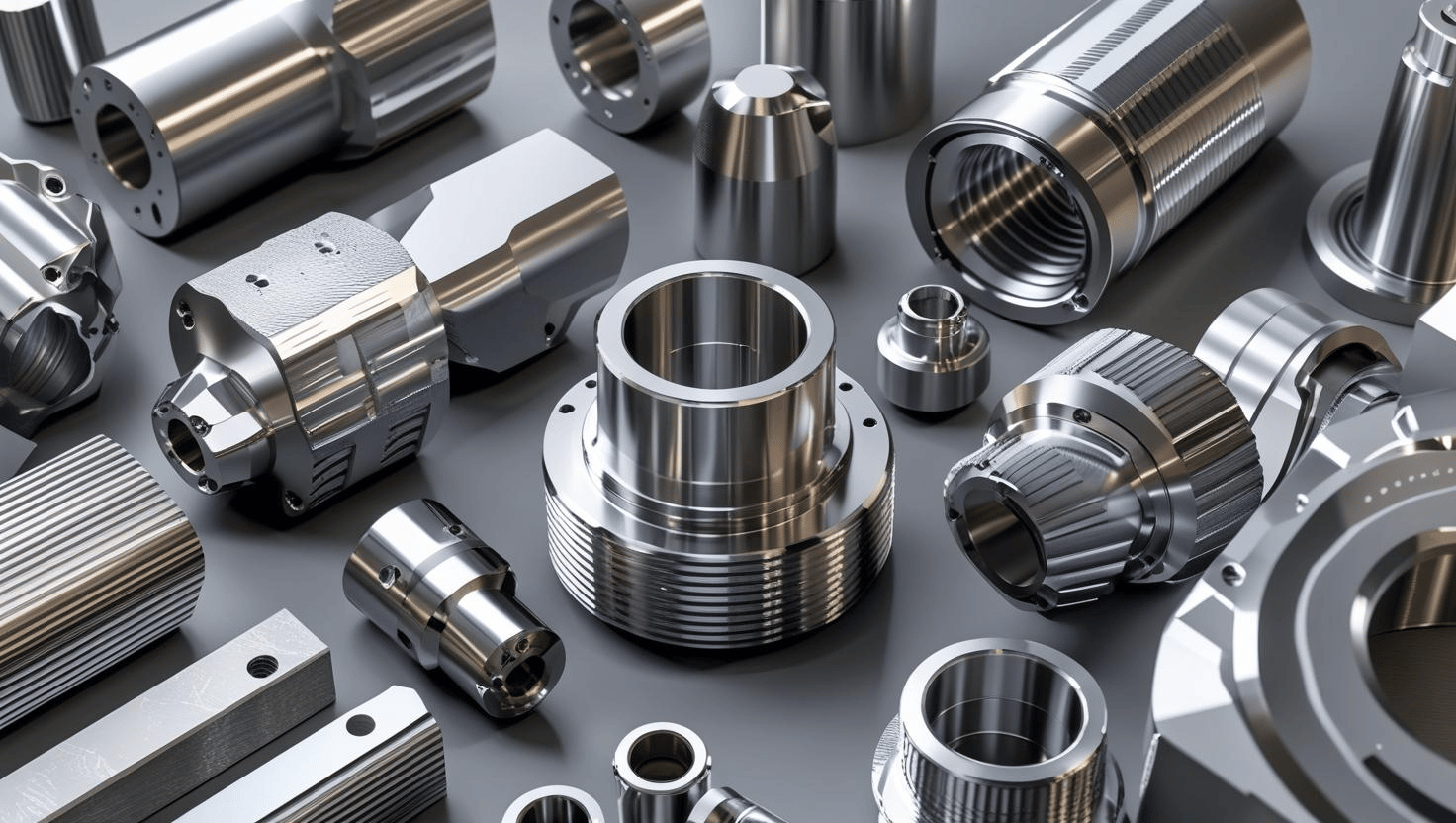

Precision Engineering

At SAGAR ENTERPRISES, precision isn’t just a process — it’s our philosophy.

We specialize in high-accuracy CNC machining and custom-engineered components that meet the demanding requirements of modern industries. From concept and design to machining and inspection, every stage of production is handled with uncompromising precision, quality, and consistency.

Our Expertise

With years of experience in CNC precision machining, mechanical engineering, and component manufacturing, we deliver solutions that drive performance and reliability across diverse sectors — including aerospace, automotive, medical, defense, and industrial applications.

We work with a wide range of materials such as stainless steel, aluminum, titanium, copper, and engineering polymers, ensuring every part meets its intended function and environmental demands.

Why Choose CNC Components?

-

Unmatched Accuracy: Every component is produced to micrometer-level tolerances.

-

End-to-End Support: From design consultation to final delivery, we manage every step in-house.

-

Reliability & Repeatability: Consistent results, batch after batch, with zero compromise on quality.

-

Customer-Focused Engineering: Every project is tailored to your exact technical and application needs.

Features and Benefits

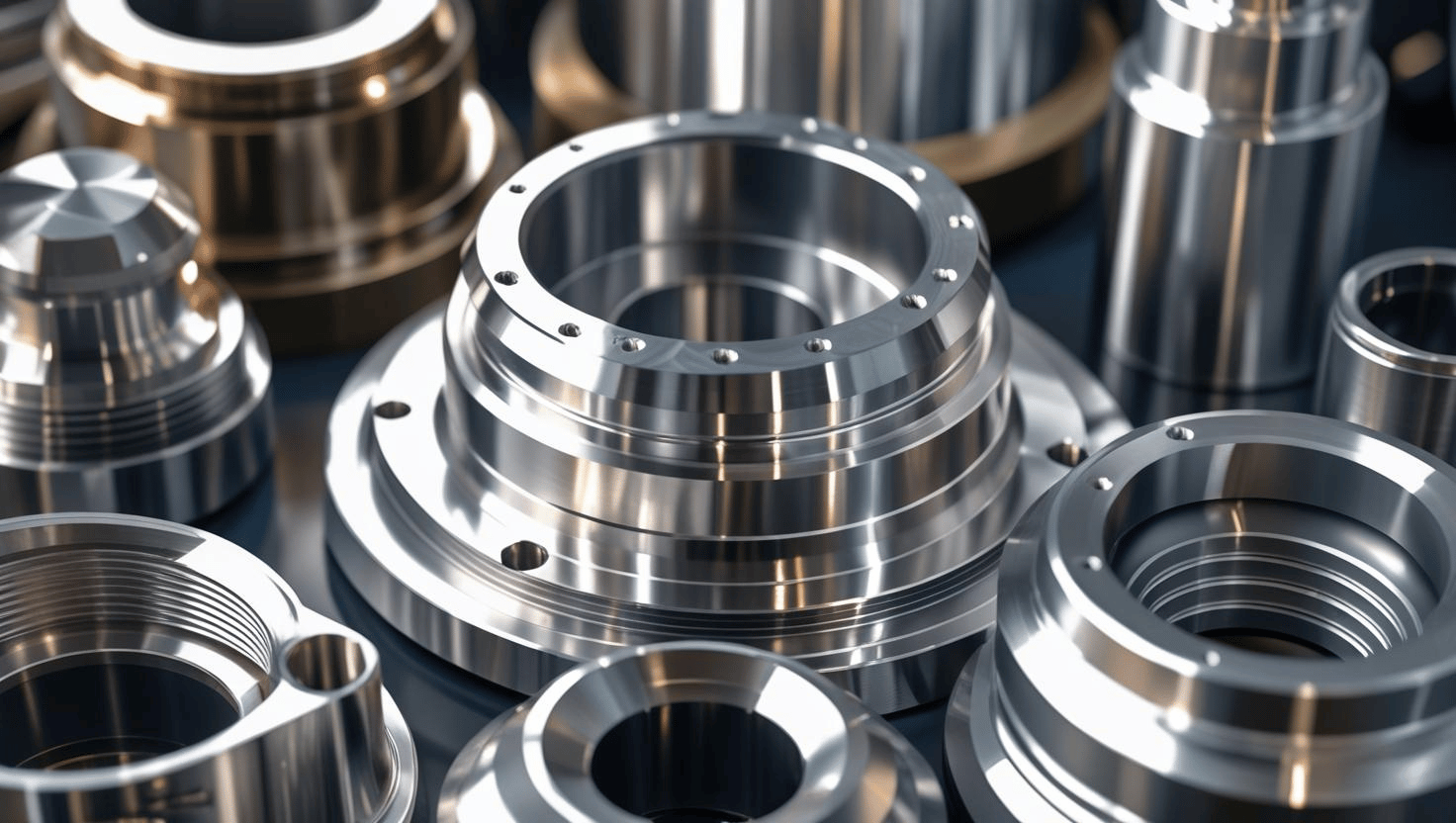

Key Features

-

⚙️ High-Accuracy CNC Machining

Advanced multi-axis CNC systems ensure ultra-precise machining with repeatable results, even for complex geometries and tight tolerances. -

🧩 Custom Engineering Solutions

Every component is tailored to your specifications — from material selection to design optimization and functional testing. -

🔍 Stringent Quality Control

Every stage, from raw material to final inspection, is monitored using advanced metrology tools to meet international standards. -

🏭 Comprehensive In-House Capabilities

From design, prototyping, and machining to finishing and assembly — all processes are handled under one roof for better control and consistency. -

🚀 Multi-Industry Expertise

Serving diverse industries such as aerospace, automotive, defense, and medical, delivering components that meet application-specific requirements. -

💡 Cutting-Edge Technology

Equipped with advanced CNC, VMC, and CAD/CAM systems for fast turnaround, high accuracy, and superior surface finish.

Key Benefits

-

✅ Unmatched Precision & Consistency

Components produced to exact specifications, ensuring flawless fit, function, and long-term performance. -

⏱️ Reduced Lead Times

Optimized workflows and in-house processes enable faster production and delivery without compromising quality. -

💰 Cost-Effective Solutions

Efficient manufacturing and material utilization lower production costs while maximizing value. -

🔒 Reliability & Durability

Engineered to perform in demanding conditions — ensuring stability, safety, and longevity in every part. -

🧠 Expert Technical Support

Experienced engineers collaborate closely with clients to develop optimal designs and practical solutions. -

🌱 Sustainable Manufacturing

Eco-conscious processes minimize waste, improve energy efficiency, and promote long-term sustainability.